News Update - October 2025

Engineering notes

By Tony Massau

In preparation for 82045's visit to Derby a few holes were drilled through the base of the smokebox into the saddle in order that the two could be secured together. Now the remainder of the holes are being drilled to complete that aspect of the job.

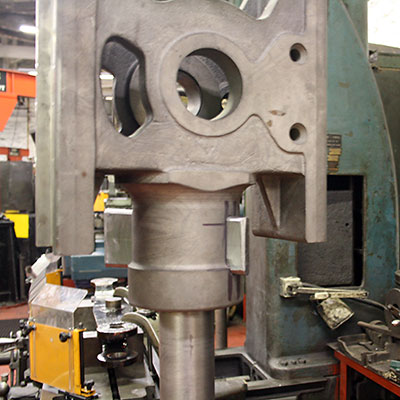

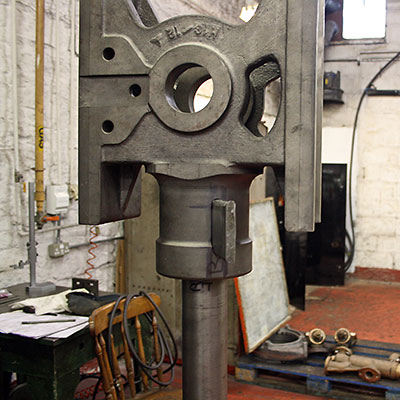

A sample taper cotter for the crossheads was produced for assessment purposes and now the final cotters are in production.

Machining of the components for the valve spindle crossheads approaches completion. Machining of the two coupling rod joint pins (aka, gradient pins) is in progress.

The superheater header passed a hydraulic test and the main steam manifold has been blanked off in preparation for a hydraulic test on that component to take place.