News Update - November 2025

Engineering notes

By Tony Massau

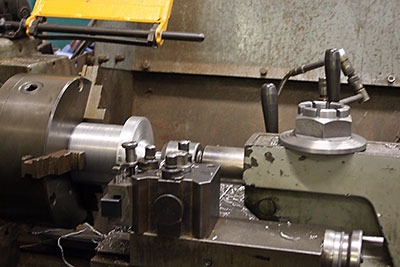

Drilling of holes through the base of the smokebox for securing it to the saddle has continued. Machining of coupling rod joint pins continues.

Alignment of the slide bars on the left-hand side of the loco is in progress. The right-hand side was done some weeks ago. Once all the data from this process is gathered the machining of the whitemetalled sliding

faces of the crossheads can take place.

A local panel beater has manufactured the complex corner sections of cladding for the firebox backhead inside the cab. Holes in these will have to be made where they fit over washout plugs and other components.