News Update - November 2023

Engineering notes

By Tony Massau

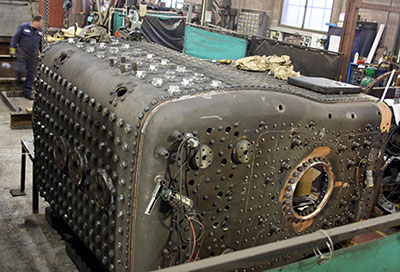

The boiler barrel has been removed from the wagon that it has been stored on for some time and has entered the boiler shop. The first stage of the work on the barrel will be marking out, drilling holes, etc. in preparing the area for mounting the dome. Recent work on the firebox has seen crown stay nuts fitted and taper washers and nuts on the transverse stays which are currently accesible with the firebox on its side.

Machining of the carriage warming reducing valve has continued as has further machining of cab window frames.

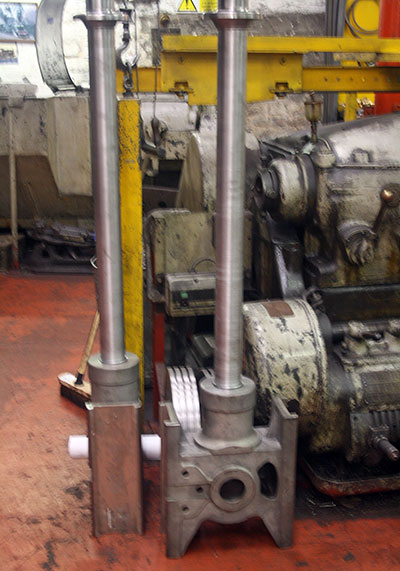

Machining of the piston rods, the tapered bore of the crossheads and the piston heads is done. Once the slide bars have been set up further machining of the crossheads can take place.

The bottom runners for the sliding cab side windows have been trial fitted and the patterns for the top runners are at the foundry for casting. Some work has been done on the arm rests for the cab side windows.

Boiler barrel sat on wagon waiting to be lifted off. Photo: Tony Massau.

Boiler barrel being lifted off the wagon. Photo: Tony Massau.

Boiler barrel being moved away from the wagon preparatory to entering the boiler shop. Photo: Tony Massau.

Outer firebox showing crown stay nuts and transverse stay nuts. Photo: Tony Massau.

Crossheads, piston rods, head. Photo: Tony Massau.