News Update - June 2024

Engineering notes

By Tony Massau

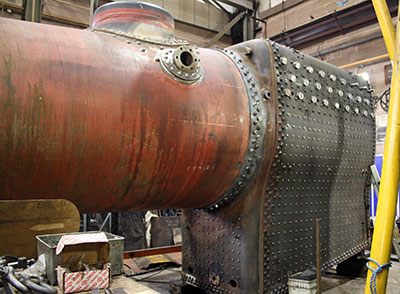

The trial fit of the boiler into the loco chassis on 3rd June was successful and the item was removed again later in the day. The joint between the barrel and firebox has since been drilled, reamed and temporarily bolted up pending the fitting of rivets. The front tubeplate is being prepared for installation in due course. Although it is still an early stage some pieces of firebox cladding sheets are being prepared and checked for fitting.

In the machine shop the valve spindle crossheads are being machined.

At The Boro' Foundry the coupling rods have had the first stage machining done and will be moving forward to final finish machining.

The cladding sheets have been temporarily removed from the cylinders in order for ease of access in fitting lubrication pipework and the associated connections. A fresh coat of paint has been applied to the inside of the cladding cover sheets.

ICYMI

We've published two further updates earlier this month: the June Edition of Chairman’s Chat which includes an overview of the recent AGM and a News Extra covering the successful trial fitting of the boiler in the chassis.

Two views of the boiler barrel to firebox joint. The first being drilled and second with temporary bolts fitted. Photos: Tony Massau.

An extension of vacuum pipework before the water tank removal which has curtailed progress for now. Photo: Tony Massau.

Two photos of the coupling rods being machined at The Boro' Foundry. Photos: Neil Taylor.