News Update - January 2025

Engineering notes

By Tony Massau

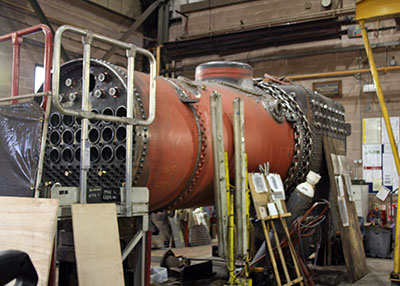

The main construction of the boiler is now complete and our grateful thanks are due to the boilersmiths for the care and attention to detail that they have taken with the build of a brand new type BR6 boiler, the first of its kind since since the early 1950's. The plan is for a company that has mobile or portable (whatever you want to call it) machining equipment to undertake the precision facing of all the pads on the barrel and firebox to ensure perfect fitment of all the ancillaries that are bolted on. An in-house hydraulic test will then be the order of the day. Steel is on order for the crinoline framework that supports the cladding. A panel beater has the contract to make the more complicated shapes of cladding around the corner sections of the belpaire firebox.

The rear edge of the smokebox is being drilled through the spacer ring in readiness for when it will be fitted to the boiler barrel. The hatch on the top of the smokebox for superheater header lifting purposes is now made.

Slide bar alignment is in progress. The first of the bushes for the coupling rods have been machined in preparation for whitemetalling. Machining is in progress for parts in connection with the valve spindle crossheads. Internal parts for the carriage warming reducing valve have been made.

More pipe support bracket fabrication has taken place in connection with the vacuum pipework.