News Update - January 2021

Engineering notes

By Tony Massau

The inevitable knock on effect of the nationwide lockdown has meant that volunteer attendance at the Severn Valley Railway has been suspended for all but the most essential and time critical of tasks in order to provide some measure of safety for the full time staff. Our volunteer engineering team has therefore not been able to continue working on 82045 since Christmas.

Contract work continues however at Bridgnorth in particular on the firebox and at Stephenson Engineering on the reversing shaft. At Philip Oldfield Engineering work continues on the regulator valves where attention is focused on the linkage and pins connecting the two valves. The machining of the new vacuum ejector is complete.

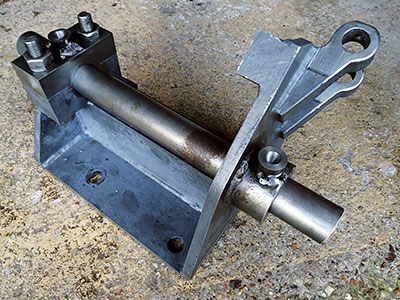

Mallens in the West Midlands have machined the brackets for the shafts of the rocking grate mechanism, as seen in the attached photos.

Publicity

By Chris Proudfoot

The photographs reproduced in this month's updates should show you that progress on 82045 is going as well as it possibly can, given the trying (to use a polite adjective) times we are all living through. Publicity has been low-key of late, but this doesn't mean that the project has been ailing: on the contrary, it is in the best of health, the main problem being that our chaps are as frustrated as hell at being prevented from carrying on with their working parties for so much of the past year. I should add that my own desk-bound duties haven't slackened, with suppliers still as busy as ever and invoices to be paid, notably one for a considerable sum in respect of a major component of the engine's motion.

The continuing uncertainty, with prognoses changing seemingly by the hour, makes it difficult to give you a likely date for the first steaming. All we can say is that we will do our very best to make it as soon as possible.

AGM 2021

We had hoped to be able to hold a proper Annual General Meeting on 24th April, but, for reasons as outlined in the last paragraph, it doesn't look as if this is going to be possible. We will continue to hope for a date sometime in the midsummer, so in the meantime may I ask you to await further notice.

Please accept the Trust's apologies for this: we don't think it would be wise, even if restrictions are eased by April, to expect a large number of people to sit together indoors in close proximity to each other.

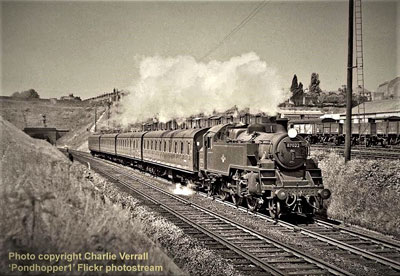

82XXX in BR days

I was delighted at the response to a couple of the photographs featured in December's updates, in particular to the shot featuring 82003 at an unknown location. Several people wrote in to enlighten me, and I would like to thank them. I suspected that the setting was somewhere in the north of England, which was correct. The engine was at Hayfield, about 20 miles east of Manchester on the edge of the Peak District. It was heading the RCTS 'Cotton Spinner' special in April 1966. This was a tour of lines in the Manchester area, and was probably the only notable duty performed by the 82XXX during their stay at Patricroft shed.

What threw me was the fact that 82003 bears the early BR totem at this late date, and presumably must have gone for scrap still carrying this. It was withdrawn in December of the same year, along with 82000/31/34. By a curious quirk, these engines seem to have been forgotten about for quite a while, as the last of them wasn't broken up until October 1968, after the end of BR steam. Of course, all four of them still had many years of useful service to offer - just another sad statistic arising from BR's unseemly haste to rid itself of steam locos, seemingly at any cost.

The other shot that provoked some comment, mostly on the National Preservation Forum, was that of 82015 at Eastleigh. My guess that the loco with smoke deflectors was a Urie H15 was wide of the mark: several folks said that it was probably a 'Lord Nelson' and I agree. The entire class was concentrated at 71A towards the end of the engines' careers (they all went in 1962), and I would guess that the photo dates from about 1961. Once again, thanks to all of you who responded.

And finally, here's a nice image by Charlie Verrall of 82022 looking very businesslike at the head of an Exeter-Exmouth local - click the image for a larger view. It was sent by my colleague Ivan Whitehouse. Thanks, Ivan!

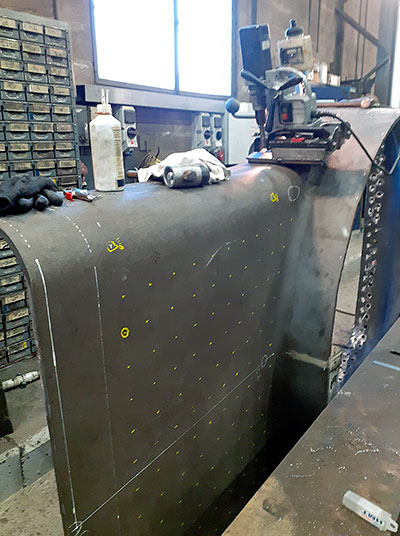

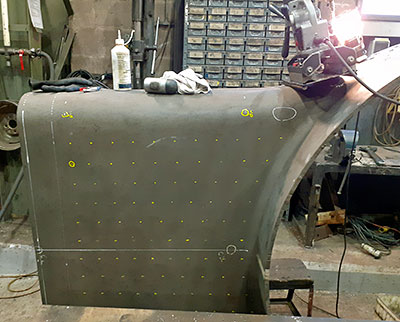

Two photos showing the drilling and marking out work on the firebox throatplate. Photos by Martin White.

SVR Boilersmith Dave Howell drilling rivet holes around the firebox flange of the throatplate. Photo: Martin White.

Some of the rivet holes around the firebox flange of the throatplate. Photo: Martin White.

Two photos showing some of the rocking grate mechanism. Photos: Peter Line.