News Update - Febraury 2025

Engineering notes

By Tony Massau

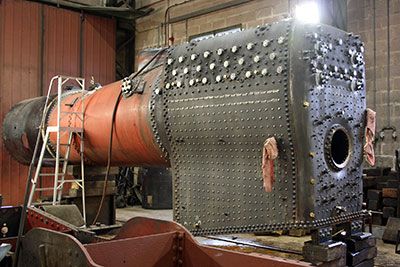

As has already been announced in the Chairman's Chat the boiler now contains water and a visit from the boiler inspector to witness a hydraulic test is expected very soon. Once this is out of the way the contractor with portable machining equipment will be visiting to machine the surfaces of the various pads on the barrel and firebox. We are already making various sections of the crinoline framework for the cladding, a job that is easier with the boiler out of the frames than within. In stating the obvious, with a new build everything has to be made from scratch, there is nothing that is available to re-use. The plan before too long is to place the boiler in the chassis in order to trial fit the various controls which in turn paves the way for all the pipe runs to be made.

The optical alignment equipment is in use for checking the alignment of the slide bars.

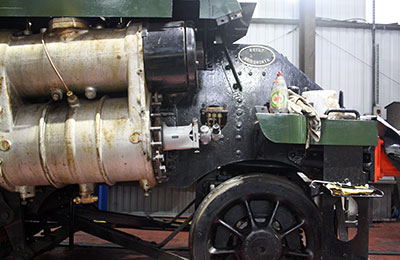

Vacuum pipework along the left side of the loco continues. The BR drawings show a lack of measurements between changes of direction etc. for some of this and carriage warming pipe runs so some "on the hoof " working out has to take place which in turn slows the job down somewhat.