News Update - February 2024

Engineering notes

By Tony Massau.

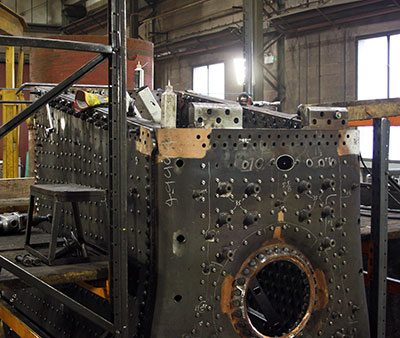

The dome is now rivetted to the boiler barrel and the foundation ring is expected to be rivetted in place very soon. There may be a trial fit of the ashpan which has been in storage for some time.

The side firebars which support the rocking sections have been cast. The blast pipe has also been cast.

The steadying brackets for the water tanks are in the process of being made.

Continuation of vacuum pipework is being resurrected along the underside of the left hand water tank which inevitably involves the tiresome task of making support brackets.

Machining of cab window frames continues.

Somers Forge at Halesowen have now been contracted to forge the coupling rods. Our previous contractor has felt the effects of loss of skilled staff in the forging department and by agreement with all concerned it was felt further delay could impact completion of our locomotive, hence the change of supplier. Manufacture of the expansion links is also subject to a change of supplier for the same reasons.

Chairman’s Chat – February 2024

Chairman's Chat - February 2024 - our regular insight into the 82045 wider world is now online.