News Update - August 2018

Engineering notes

Some machining of the axleboxes for the pony truck wheels was done some time ago. The machining preparatory to whitemetalling is now being done and is proceeding well. The axleboxes will then be sent out to a specialist whitemetalling company and upon return final machining to size will be undertaken. The bushes have been pressed into the king pin holes in the radial arms and various component parts of the pony trucks that have been in storage are coming out of hibernation. There is much to do however before we achieve completed pony trucks.

Activity is also focussed on the slide bars. The security holes at each end were deliberately not drilled at the time of manufacture. We are now aligning the slide bars into their correct positions on the loco, marking out the hole locations, drilling, refitting and reaming.

Pipe clips are being made for the lubrication pipe runs.

Work continues on the cladding around the cylinders.

Machining has resumed on the last of the steam chest liners. Three are already complete.

Publicity

Steam Railway continues to give us good coverage each month, and I'd like to thank my regular contact at the magazine, Assistant Editor Toby Jennings, for his consistent support for 82045. Actually, recent publicity regarding a possible future on the mainline for the locomotive has landed me in a bit of hot water with some of our members.

It's a case of mea culpa, I'm afraid: as a technophobe, I should have realised that not everyone is internet-connected (I sometimes wish I wasn't, but needs must) and that consequently, not everyone saw the paragraphs in the updates for June and July on which the magazine based its news stories. I will be writing a piece for our September Newsletter apologising for this unintended discourtesy and inviting further opinions on the subject: the die is cast now, but I would still like to hear from anyone with anything constructive to say.

Lookout in the next couple of months for an article about 82045 in Steam Railway's regular feature Inside Track. The same issue will also carry an appeal leaflet - an updated version of the old "heart" leaflet-aimed at raising funds for the boiler and firebox assembly. Although things look good, we are not home and dry yet and I want to make sure that we always have funds available to meet outgoings, especially as the plan to contract more work out is going to increase costs.

The Publicity sub-group has also got one or two tricks up its sleeve, but it would be premature to make any announcements just yet.

Sponsorship

I'm very pleased with the success of our occasional sponsorship feature in the updates. The last appeal was for components for the pony trucks, and at the time of writing, only one of the items listed is still available. This is one of the two side check spring bars, going for £900. Please get in touch with Chris if you'd like to sponsor this last item. Many thanks to all those members who have put their names against the other components: you've helped bring forward the day when a 0-6-0 becomes a 2-6-2!

Further items for sponsorship will be listed as soon as my engineering colleagues tell me what they would like to advertise.

82045 in New Zealand!

Life member Mike Jack, who lives in Auckland, is building a five-inch-gauge live steam model of one of the last two 82XXX tanks to survive in BR service, either 82019 or 82029. Mike pays an annual visit to the UK, and spent a day at Bridgnorth earlier this month, when he met members of the engineering team as well as Chris and had a good look around the loco.

Mike is a skilled engineer, and brought along with him a caseful of components for his model - including a driving wheel and firebox support bracket - all cast by himself. Having seen the full-size items, I can tell you that they are pretty impressive. He is planning to build a second engine, this time a model of 82045, which he would like to donate to the Trust as a fundraiser. We discussed ways in which this could best be marketed - raffle, auction, sealed bid subject to a minimum price for example - and will be working together to ensure that this is done in the most effective way. Mike visited 82045's footplate and was able to pose for a photograph on the driver's seat.

This is a seriously big model, and he explained to Peter Line and your Publicity Officer - the former understanding exactly what he meant, the second standing there like an amazed ape - how he proposes the cut-off should be controlled from the truck on which the driver sits, via the left-hand side of the bunker (where the bottom left lamp bracket is situated) and a universal joint working the bacon slicer reverser handle in the cab. I think this model engine is going to be one superb piece of kit, so if anyone out there would like to make an offer for it in advance, please get in touch with Chris.

The driver’s reversing mechanism. Photo: Tony Massau.

John Pagett pressing the bush into the king pin hole of one of the pony truck radial arms. Photo: Tony Massau.

Reaming the slide bar bolt holes at the rear of the right hand cylinder rear end cover. Photos: John Pagett.

Mike Jack on the footplate of 82045 at Bridgnorth on 15th August. Only the sky viewed through the cab front - and the cream cracker tin in the bunker - tell you that he's not about to depart all stations to Salop! Photo: Chris Proudfoot.

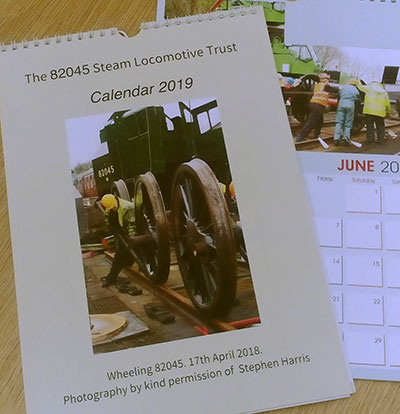

Our 2019 calendar is now ready and may be purchased from Barbara at a cost of £7.50 (includes P+P). The calendar is a pictorial memento of the wheeling of 82045 in April 2018 and we are grateful to our friend and supporter Steve Harris for his coverage of the days events and for allowing us to use his images.

Please send a cheque payable to “The 82045 SLT “ (£7.50 per calendar) and your address to Barbara who will post your order to you.